Causes of rhodium jewelry and step by step process

42836

42836Rhodium plating — an electroplated cover of metal with a thin layer of rhodium. It is widely used in jewelry and has several advantages among other types of coatings. True connoisseurs of exclusive and expensive jewelry know something about it, but we have prepared information that will allow you to become better informed with this jewelry coating.

Why jewelers use rhodium plating?

It all depends on what kind of rhodium interests you, because there are white and black.

White rhodium is used for two reasons:

1. Aesthetic appearance. Many people, choosing white gold, ask us to cover the decoration with white rhodium, because they do not like the yellow tint of white gold. Therefore, for those who love white shades, this coating will be the ideal choice. Jewelry with this covering always looks luxurious.

2. Protection. One of the reasons for applying this coating is to protect the jewels from damage. After all, the film of rhodium metal is quite stable to mechanical and chemical factors. But It is worth mentioning that the layer is quite thin. This means that the film can be easily damaged or scratched even in domestic conditions.

Black rhodium is used for

Black rhodium actually plays the same role as oxidation. We put it to add for the ring contrast and highlight its relief. However, why we use rhodium if it is possible to cover with oxidation? The fact is that gold, unlike silver, cannot be oxidized.

What is the difference between white and black rhodium?

The first difference is in color, second — functions that perform, third — is the result.

Black rhodium completely never remains on the jewelry, since the task is not to make the product black, but to emphasize the relief.

With white rhodium, the decoration is covered entirely and remains unchanged. After all, the main task is to make the jewel white.

Rhodium technology

As with the oxidation, you must first prepare the product for work.

1. We degrease the jewelry and clean it in an ultrasonic cleaner so that there is no dust or fingerprints on it.

2. We wash the product with distilled water because the decoration must be bathed in an absolutely pure form.

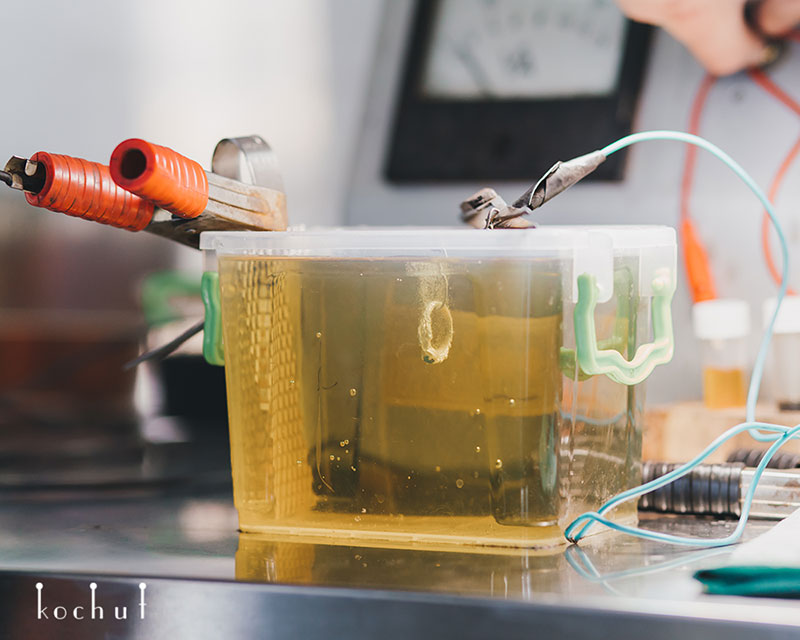

3. Dilute concentrated rhodium, immerse the product (cathode) and the metal plate (anode), which will be an excellent conductor of electric current.

4. We apply electrical voltage and observe the passage of the reaction, which is accompanied by an active formation of bubbles on the cover of the product.

5. Mark 2-3 minutes. After all, applying a layer of rhodium on the ring takes more time than on earrings.

6. Remove from the solution and wash.

7. Evaluate the quality of the coating.

Effect of rhodium on the skin and an allergic reaction

One of the reasons for using a metal film — insure yourself against the manifestation of an allergic reaction. If you are allergic to silver or gold, you must ask the craftsmen to treat the jewelry with rhodium. It is worth mentioning that in some cases it is also possible to cover the local parts of the jewelry. It is mainly used for hooks of earrings so that the ears do not come into contact with silver or gold.

Rhodium is a precious metal and does not contain impurities that can cause an allergic reaction, so it does not interact with human skin and is hypoallergenic.

How to distinguish the rhodium silver from the rhodium gold?

Visually it's impossible because the tint on both metals is the same. The only way to find out what is hiding under the covering is to sand the created pellicle.

True, there is another way. If you take two identical jewels in the same size, you will be able to distinguish them by their specific weight, because gold is heavier than silver. For example, “Twig” in the 17th size of gold will weigh 7.5 grams, and silver — 5 grams.

Leave a comment via Facebook:

Kochut and our partners use cookies on this website. Some of them are required for the site to function properly, but the following cookies are optional:

— cookies that analyse website usage;

— cookies used to personalize the site;

— cookies used for advertising and social media purposes;